SeaWall (2021)

Seaweed fibreboard (variable sizes)

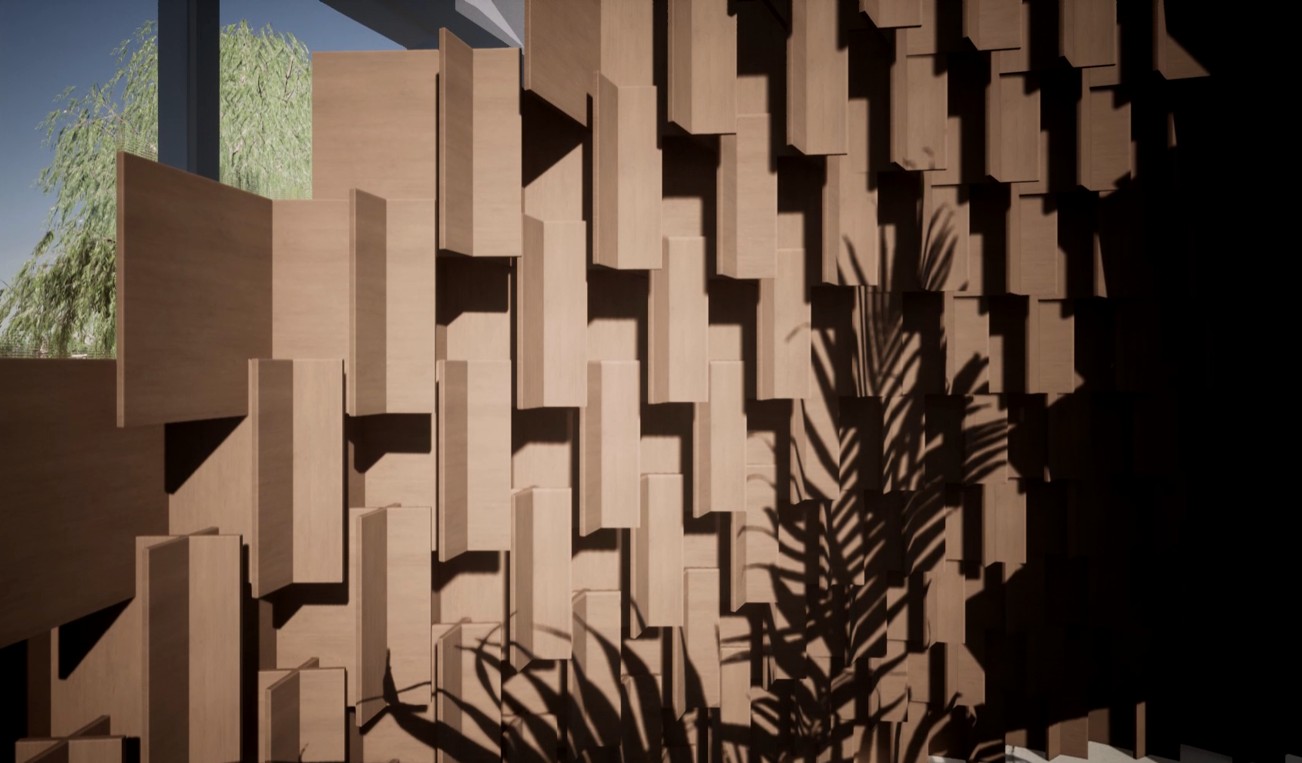

SeaWall stands as a transformative, modular, and interactive room divider, a collaborative creation involving myself and three other students from the Robotic Production & Circular Materials minor.

SeaWall is made of SeaWood, a natural, compostable and chemical free fibreboard made by BlueBlocks.

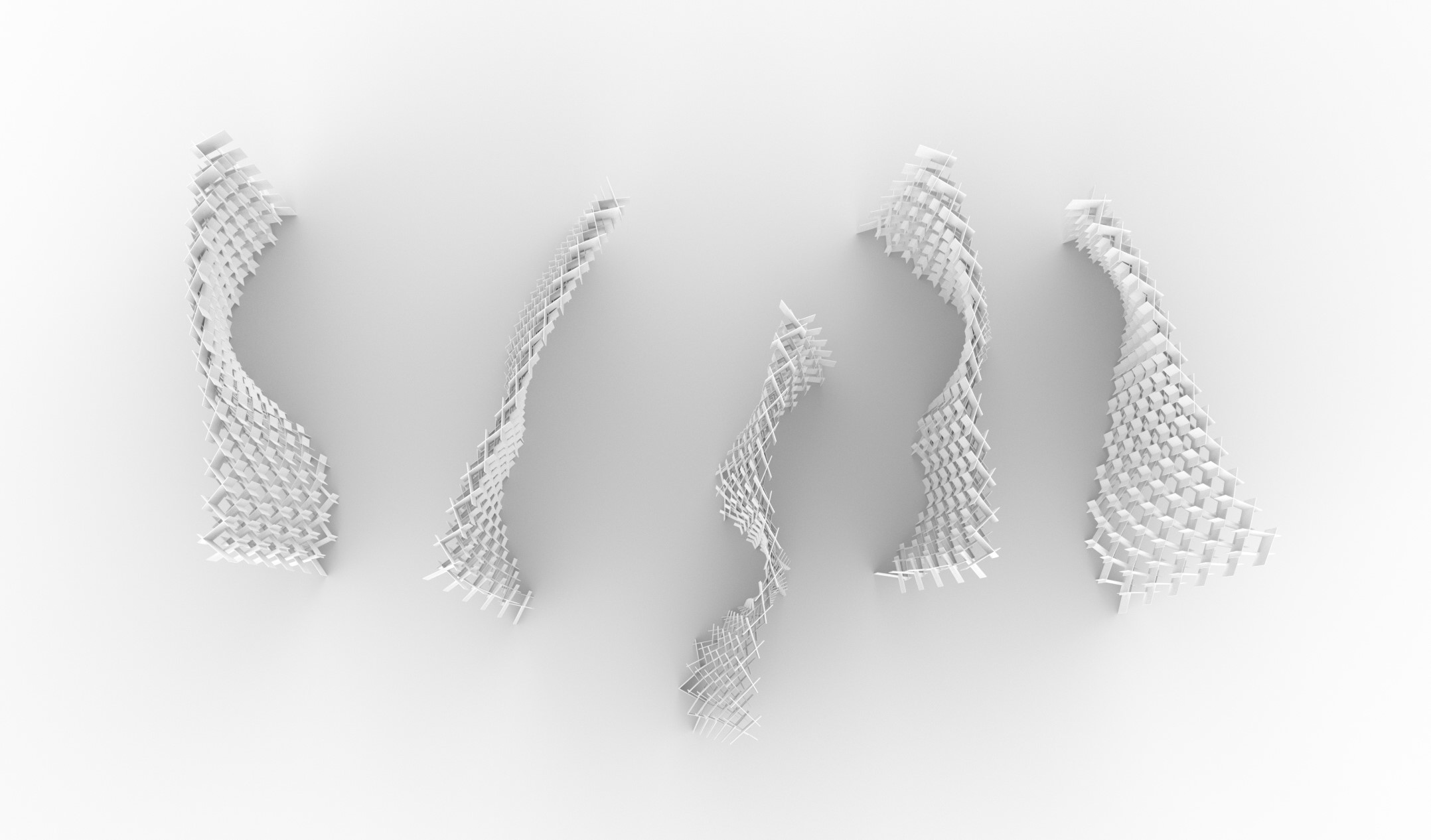

The challenge was to find an application for SeaWood within the built environment. SeaWood panels are thick, firm and have sound dampening properties, which makes it an ideal material for acoustic panels. With the use of algorithmic design in Grasshopper, a parametric room divider was generated.

In each panel, a unique ID number and QR-code is engraved. By scanning the QR-code, clients are led to an app that calculates the ideal parameters for the space where SeaWall would be applied. The app uses AR to show the client what the wall will look like. With this ordering process, each panel is produced on demand, generating as little material waste as possible.

To make SeaWall easy to repair, the app can be used to send an order to BlueBlocks. To do this, the client simply scans the QR-code of the panel that needs to be replaced and the app sends the information to BlueBlocks. The customer mails the broken panel to BlueBlocks, where this panel is shredded to reuse the material. After this, the customer receives a new panel in the mail. Due to the modular nature of SeaWall, clients can easily replace the panels themselves.

During the project, two plywood prototypes were produced: a small scale model of one of the iterations of SeaWall and a full scale model of four connected panels.

Project partners: Yassmina El Hassnaoui, Jakob de Konink, David Holmes